Model no.15:

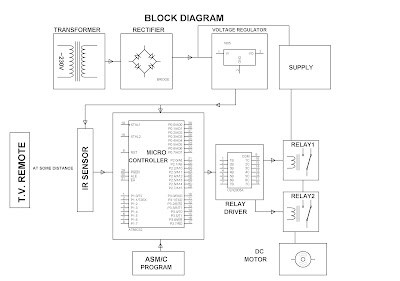

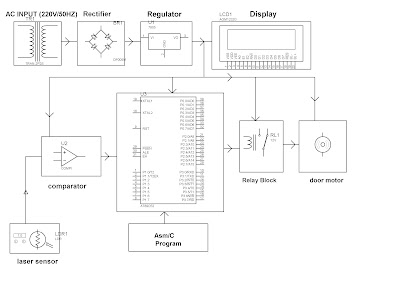

The main objective of the project is designing a programmable sequential switching of any load using embedded system based microcontroller concept. It uses microcontroller from 8051 family which is of 8-bit. The development of this application requires the configuration of microcontroller architecture that is the selection of the machines, and writing debugging of the application program. In this project, the clock plays an important role, where it is used in the following mode i.e., the set mode, auto mode and manual mode for controlling different machines. In set mode, through the digital clock the machinery will run based on/off and on time where as in auto mode they will run by default settings and finally in the manual mode the real-time systems used extensively in industrial control applications can run depending on the user’s need and flexibility. The power supply consists of a step down transformer 230/12V, which steps down the voltage to 12V AC. This is converted to DC using a Bridge rectifier. The ripples are removed using a capacitive filter and it is then regulated to +5V using a voltage regulator 7805 which is required for the operation of the microcontroller and other components.

For more details about this project, please visit http://www.efxkits.com/project-kit/microcontroller/1007.html

HARDWARE REQUIREMENTS:

Microcontroller unit, LCD (16x2), ULN2003, Relays, Resistors, Capacitors, LED, Crystal oscillator, Diodes, Transformer, Voltage Regulator, Push buttons, Loads.SOFTWARE REQUIREMENTS:

Keil compiler, Language: Embedded C or Assembly.

Like us on Facebook.

Follow us on Twitter.

Visit our Website